Master, Full Time, Part-Time

- Campus Wels

- Email sekretariat.ab@fh-wels.at

- Telephone +43 5 0804 43095

- Download info sheet Contact us

News & Highlights of our students

Praxis & Projects

Highlights from our students, their projects and trips during their studies.

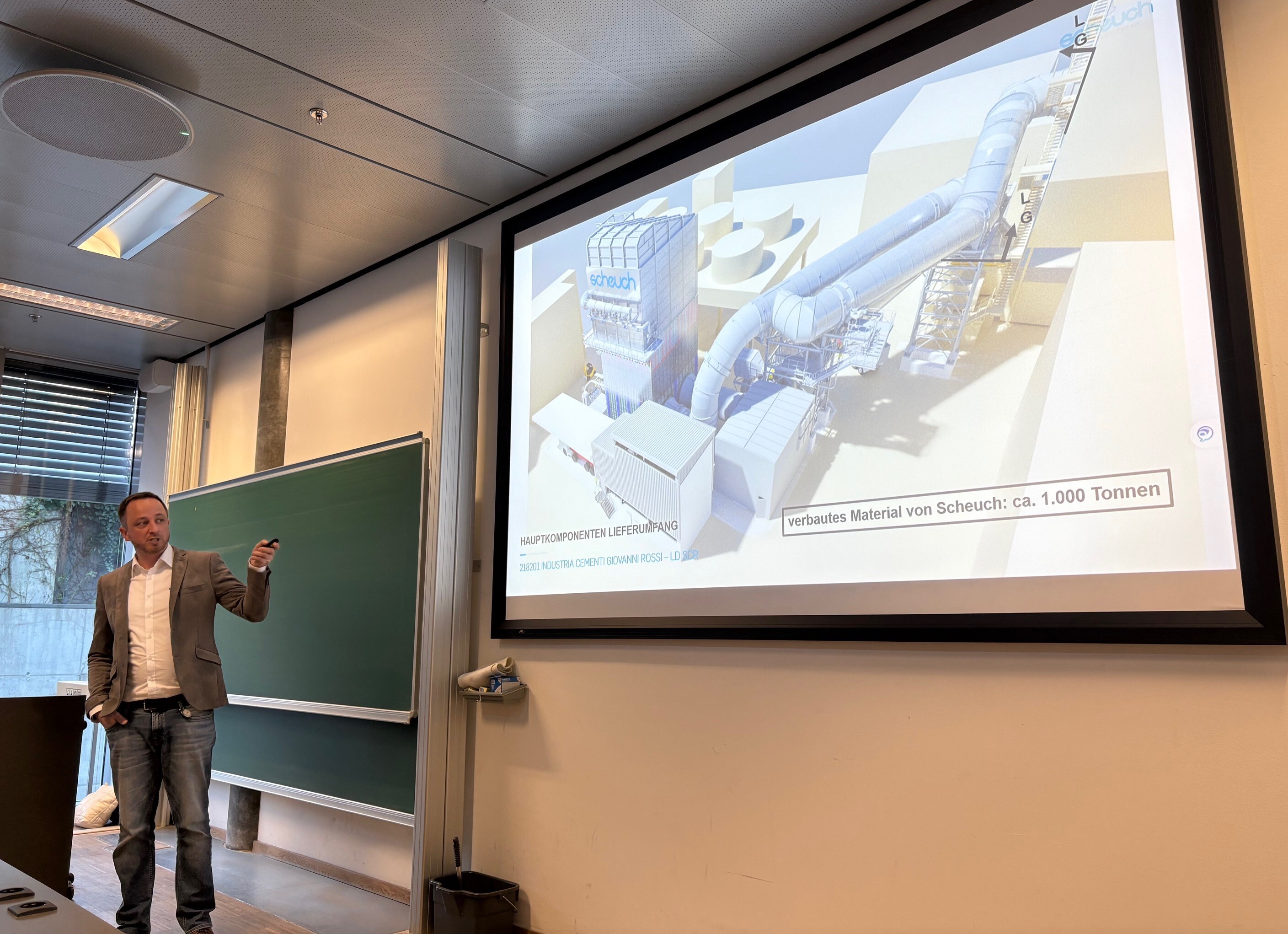

🚀 Come together with our premium industry partners

A great review of this year's ‘Come together with the industry’ with our premium partners ZAUNERGROUP & Scheuch GmbH and the students of the degree programs ‘Process Engineering Production’, ‘Bio- & Environmental Technology’ and ‘Plant construction management’.

🎉 The highlights?

- Current developments & research topics of the degree programs

- Insights & insider know-how from Andreas Berger (Head of Process Engineering and Technology at Scheuch), who immersed himself in one of the high-tech projects with the students.

- Real insights from ZAUNERGROUP into one of their largest ongoing plant construction projects with a well-known tech company - explained by the senior project manager of this major project himself.

Highly interesting discussions & a holistic project view for the future project engineers & international project managers. The next ‘Come Together’ is already in the starting blocks for autumn 2025....

It's Not WHAT We Teach, It's the WAY We Teach...!

Theory meets real power! Our plant engineering students gained impressive insights into the world of heavy transport and lifting technology during an exclusive excursion to Felbermayr, one of europe's leading transport company.

The highlight? Driving a giant crawler crane yourself! Experience technology up close - that's exactly how hands-on learning works!

Welcome on board > Partnership with technology leader!

We are proud to announce the start of our close partnership between the degree programm "Plant Construction Management", "Bio- & Environmental Engineering" and "Process Engineering" with the Scheuch Group - a world-leading technology company for air pollution control in the industrial sector!

Students meet industry - AGRANA Starch

Our students of the degree program ‘Plant construction management’ had the impressive opportunity to explore the world of AGRANA Starch @ Aschach an der Donau – a famous industry company in the heart of upper austria! With our premium partnerZAUNERGROUP, we introduce our students ‘up close’ to plant engineering... a big thank you for the TOP support from one of leading companies in the plant construction industry of austria.

Come Together with the plant construction Industry

A great review of this year's ‘Come together with the industry’ event with our partner company ZAUNERGROUP and the master students of ‘Plant Construction Management". Keytopics of the event: Insider knowledge in the planning of current plant construction projects and current research topics in plant construction industry (such as ‘AI, refurbed products and the latest possibilities in after-sales)

The highlight? Real insights from Zaunergroup into the world's largest project for CO2 storage, where Zaunergroup was instrumental in the realization and which was presented by many well-known media (e.g. CNN link: https://edition.cnn.com/2024/0....).

Students of plant construction management meet industry

Our students of the degree program ‘Plant construction management’ and ‘Process Engineering’ had the impressive opportunity to explore the world of LAT Nitrogen!

Many thanks to Richard Auberger and the LAT team for an excursion ‘up close’ to the industry.With our premium partner ZAUNERGROUP, we introduce our students ‘up close’ to plant construction management... a big thank you for the TOP support.Stay tuned for more exciting excursions and insights from our plant engineers & process engineers! 🚀⚙️

Plant construction management meets top industry

We are proud to announce the start of an in-depth partnership between the master degree program "plant construction management" & "process engineering production" with the Zaunergroup - a leading company in plant and industrial piping construction - for the year 2024 & 2025!

This future collaboration combines academic excellence with the practical experience of a leading company. Our students will gain exclusive insights into the international project business to take their studies to a new level.

Company Schwingshandl sets new impulses in multi-project management

With his master's thesis under the supervision of Dr David Kronawettleitner, Lukas Sandmair carried out a holistic view of project management for company Schwingshandl automation technology and analysed the interaction of all projects at the company. The developed project management solutions as a result will provide significant impetus for the multi-project management of future intralogistics projects.

Use of artificial intelligence in plant construction management

In his master's thesis on the use of artificial intelligence in plant construction projects under the supervision of Dr David Kronawettleitner, Philipp J. Moser investigated how AI can improve efficiency, precision and flexibility in plant construction management. He showed how AI-supported processes can revolutionize the planning, implementation and monitoring of projects.

Best-in-class turnaround management @ LAT Nitrogen

Richard Auberger - graduate of plant construction management - analysed and optimized the turnaround management as part of his master's thesis under the supervision of Dr. David Kronawettleitner. With more than 15 years of experience in turnaround management at LAT Nitrogen, Richard was able to comprehensively analyse the challenges, difficulties and potential for optimization in the turnaround. Due to the high number of (partly overlapping) activities, a turnaround is an economic and technical challenge for companies for good reason. Thanks to the additional expertise, the 2024 turnaround of LAT Nitrogen could be described as a ‘best-in-class’ approach.

Women´s power @ degree program plant construction management

In our degree program, 5 impressive female students show that the future in the international project business is FEMALE! Our talented female students Marlene Oberpeilsteiner, Sandra Kusel, Viktoria Schachinger, Carina Pieringer and Farah Alkurdi show that our degree program "plant construction management" with a mix of technology, business, law and many project cases is inspiring.

‘We are proud that we have seen a trend in recent years towards more women opting for our degree program with a focus on project management. With 233 graduates since the program started in 2008, these talented female students are real role models for a versatile education!’ Dr David Kronawettleitner

Cooperation between plant construction management & company Felbermayr

In a new cooperation between degree program "plant construction management" and company Felbermayr Transport- und Hebetechnik GmbH & Co KG, we are opening the doors to practice-oriented teaching of course content ... directly from the best in transport and lifting technology.

With Michael Lehner - a Felbermayr employee with a wealth of project experience - he will share his expertise in lifting and transport technology with our students in a practical way on (large-scale) projects!

Smurfit Kappa Nettingsdorf with a clear commitment to the „Green Deal“

As part of his master's thesis for Smurfit Kappa Nettingsdorf AG & Co KG, Patrick Pühringer designed a biomass plant with possible combustion of rejects under the supervision of Dr David Kronawettleitner. The resulting implementation concept demonstrates that recyclable materials such as bark, fines and rejects can be used to generate energy at the site in order to significantly expand heat and energy production from renewable energy sources.

Primetals Technologies optimises project risk management

Bernhard Eder scrutinised risk management as part of his master's thesis for Primetals Technologies Austria GmbH during his studies. Undetected or neglected risks can lead to problems and unexpected costs in projects. This potential risk can be countered with forward-looking and efficient identification, analysis and assessment in the sales and realization phase.

Innovative knowledge management @ Zaunergroup

Process engineering graduate and current plant construction management student Carina Pieringer has developed an innovative approach to internal knowledge management for company ZAUNERGROUP as part of her bachelor's thesis under the supervision of Dr David Kronawettleitner. A large number of companies are faced with the question: How can knowledge be stored, accessed and made usable within the organisation in the long term? ‘This issue will be addressed with a well thought-out system, clear routine processes and a user-friendly tool in order to do justice to future plant construction projects.

Optimization of project planning for heat treatment plants

As part of his master's thesis, plant construction management student Michael Klostermann has improved the design process for industrial heat treatment plants at EBNER Industrieofenbau with new approaches. The created design guideline provides a guideline from calculating to contract specification of complex plant systems.

Student of plant construction management increases production capacity of a production line by 135%

Dynamic market requirements and the rapid cycle of product changes require existing production lines to be optimized. This problem can be countered by an innovative, modular design of the production lines. ‘These optimizations will ensure that BWT's production remains competitive in the future. In his master's thesis, student Michael Schneebauer, together with Dr. David Kronawettleitner, analysed an existing production line for the manufacture of water softeners, which is already in use in England, and identified a wide range of potential improvements. Production capacity can be increased by 135 per cent with the same number of staff,’ says Schneebauer.

Student of plant construction management develops a strategy concept for salg bucket replacement for voestalpine

The graduate of plant construction management Rainer Lettner has developed a technical and commercial realization concept for a new slag bucket strategy as part of his master's thesis for voestalpine Stahl GmbH in Linz. ‘In my thesis, I analysed the process of emptying the slag buckets and the associated problems, evaluated them quantitatively and qualitatively and drew up an improvement concept. A 5-year strategy was derived from this,’ says Lettner happily.

"Turbo"-process at Zaunergroup reduces time required for quotation calculation by 50%

As part of his master's thesis, Lukas Jaksche a graduate of plant construction management developed with his supervisor Dr. David Kronawettleitner a new calculation process for piping systems for data centre projects at Zaunergroup. The focus is on a calculation with rapid quotation submission, but this limits the risk of calculation errors. ‘This issue can now be addressed with a standardized and time-optimized calculation process - including access to a digital database - in order to be able to respond flexibly to the project circumstances,’ explains Jaksche.

Company FILL sets new standards in project risk management

As part of his master's thesis for Fill Gesellschaft m.b.H., DI Robert Steinmann BSc MSc, graduate of plant construction management took a close look at project risk management together with his supervisor Dr. David Kronawettleitner. Undetected or neglected risks often lead to massive problems and unexpectedly high costs in later project phases, as is also the case in mechanical engineering. This potential danger can only be countered with a forward-looking and efficient approach to identifying, analyzing and assessing risks.

Competitive advantage through modularization at Zaunergroup

Zauner Anlagentechnik GmbH implements large-scale projects in the energy, life science (pharmaceuticals, biotechnology) and, in recent years, increasingly in the data centre sector. In order to stand out from the competition, the realisation time and costs of these projects are to be reduced while maintaining the same level of quality. Under the supervision of Dr David Kronawettleitner, plant construction student Dominik Landerl worked on a modular construction kit system in his master's thesis, with which individual project components can be modularization and standardized.

Modernisation concep for ladle furnance 1 at voestalpine

Plant construction management graduate Markus Thumfart developed a modernization concept for ladle furnace 1 at voestalpine Stahl GmbH in Linz as part of his master's thesis under the supervision of Dr. David Kronawettleitner. In order to be fit for future challenges and the increasing quality requirements, a holistic technical and organisational analysis of the revitalization options was carried out. ‘The modernization concept developed will increase the quality of the product mix and improve the production spectrum in the future,’ says Thumfart.

Plant construction management student optimizes project handling at Zaunergroup

Daniel Schatzl, a plant construction management graduate from Wels, has optimized the project management of Zaunergroup in Wallern as part of his master's thesis with his supervisor Dr David Kronawettleitner. Using real industrial plant construction projects, the potential savings were extrapolated. The results showed that with the help of the new software products, project profits can be increased by up to €100,000, depending on the size of the project.

Service-"evolution" in after sales

In his master's thesis, graduate of plant construction management Matthias Harreither BSc, took a closer look at after-sales service together with Dr David Kronawettleitner and the Scheuch team. Based on best practices and trends in the service business, the current portfolio and the general conditions in the company were analysed and optimization potential for the after-sales area was derived.

Centrepiece commissioning - Significant cost savings for remote commissioning

Plant construction management graduate Tobias Wuschko investigated plant commissioning as part of his master's thesis for EREMA Engineering Recycling Maschinen und Anlagen GmbH under the supervision of Dr David Kronawettleitner. Unplanned restrictions such as natural disasters or travel restrictions repeatedly lead to more difficult commissioning, including during the COVID-19 pandemic. This problem can be counteracted by means of risk-minimized commissioning ‘remotely’, thus decoupling this key phase.

Contact

EmailE sekretariat.ab@fh-wels.at

TelephoneT +43 5 0804 43095

Quick Links

I'll help you choose your study program.