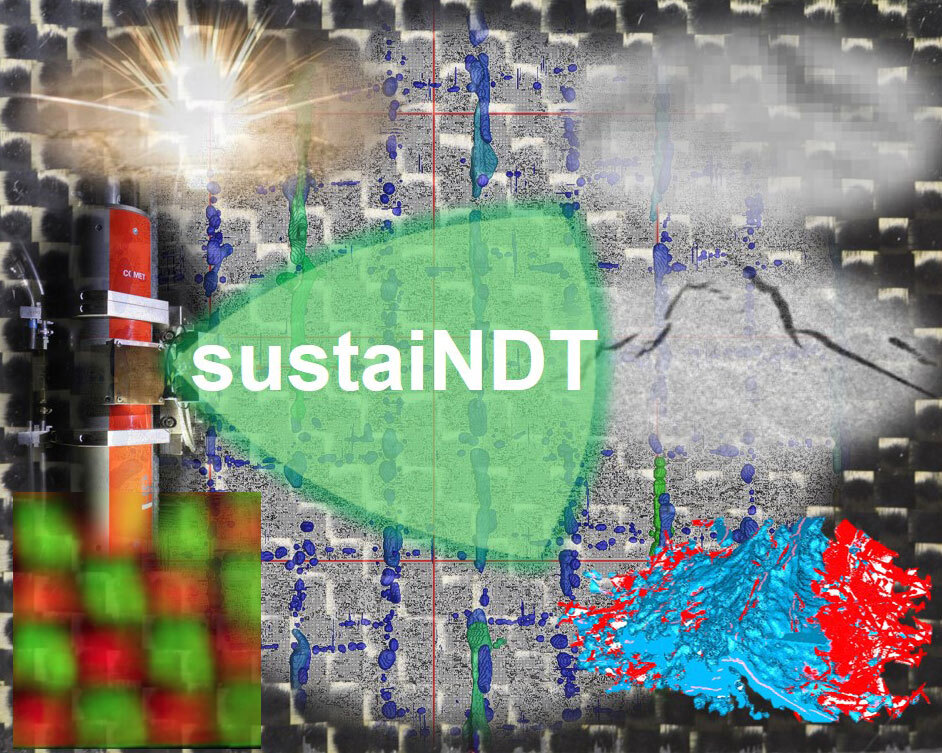

sustaiNDT

AI Super-Resolution & Fast-Inspection NDT Upgrades as support for sustainable manufacturing and repair processes.

Projektlaufzeit:

01.05.2024 until 30.04.2027

Lead-Partner:

Project-Partner:

Schiebel Elektronische Geräte GmbH

Funding:

FFG - Die Österreichische Forschungsförderungsgesellschaft.

Projekt goals:

- Further development and significant improvement of AI-based NDT methods

- Combining super-resolution technology and AI approaches to obtain high-resolution CT images of large aircraft components and generate detailed 3D microstructure images.

Projekt description:

Like all manufacturing sectors, the aviation industry, in particular, is facing one of its greatest challenges: reducing emissions while simultaneously increasing recycling rates and ensuring product quality and safety. In this context, non-destructive testing (NDT) plays a crucial role in the development of lightweight concepts and the use of sustainable materials. Traditional inspection methods such as visual inspection or ultrasound testing are time-consuming and often unsuitable for complex components and new manufacturing processes.

The integration of artificial intelligence (AI) into NDT can expedite and streamline this process, particularly through improved error detection and detail recognition. By combining AI with modern NDT methods such as micro-computed tomography (CT) with Super-Resolution technology, high-quality NDT data can be generated for composite and hybrid components as well as large aircraft parts.

The main goal of this project is to advance and significantly improve AI-based NDT methods to enable faster and more reliable inspections and enhance production quality. These advanced NDT methods are crucial for their integration into future production processes, including the use of recycled carbon fibers, thereby promoting the innovation processes of the involved partners and strengthening the focus on new lightweight concepts.

In the sustaiNDT project, Super-Resolution technology is combined with AI approaches to obtain high-resolution CT images of large aircraft components and generate detailed 3D microstructure images. This allows even the smallest damages to be detected, providing valuable information for repairs before they lead to more significant issues. This project introduces an innovative AI-based approach in NDT and supports the adoption of AI technologies in production as well as the development of repair concepts.

The developed testing procedures in sustaiNDT can be used both for new production processes and on-site, saving time and costs while significantly enhancing product quality and safety. The combination of AI and Super-Resolution enables the high-resolution detection of defects, including cracks, pores, and delaminations. Early detection of damages allows for immediate repairs, reducing maintenance costs and extending the lifespan of products.

The multidisciplinary concept of sustaiNDT strengthens Austria's position as a competent partner in the aviation, lightweight, and technology sectors and contributes to European aviation activities. The results achieved in sustaiNDT can also be applied to other industries requiring non-destructive testing. Through the results obtained in sustaiNDT, the transition to environmentally friendly, more recyclable materials can be accelerated, significantly extending the lifespan and operational times of individual components

Contact

DI (FH) Bernhard Plank, MSc

Research Project Manager

University of Applied Sciences Upper Austria Research & Development GmbH

Stelzhamerstraße 23 | 4600 Wels/Austria

Tel.: +43 (0)50804-44408

E-Mail: bernhard.plank@fh-wels.at

Quick Links

I'll help you choose your study program.