Non-destructive testing & Materials Characterisation

3D analysis and material composition Surface extraction for finite-element simulation Structure and defect analysis Density studies and porosity determination Fibre extraction and -orientation

Light Metallic Components

Detection of voids - μXCT is ideally suited for the detection of voids in light metals. Through appropriate automatic segmentation programs (eg. Defect Analysis of vgstudio MAX) the spatial location and the size distributions are presented.

Metals

Non-metallic inclusions and voids in steel - Despite constant improvements in metallurgy and casting technology in steel applications, the purity is still an essential quality criterion. Therefore, it is essential to know the abundances and distributions of sulphide inclusions.

Polymeric Components

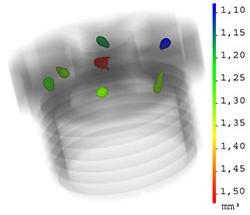

Detection of flaws - An application is the cavity evaluation, in which the voids contained in the plastic are detected using a special software tool, which segments the transitions between materials and voids in three dimensions with special image processing algorithms. The resulting data can not only be evaluated statistically, but also illustrated directly on the component with a color code corresponding to the size distribution.

The oxide-ceramic fuel cell

The fuel cell research at the site of the FH OÖ Wels is focused on mikrotubular SOFC's (Solid Oxide Fuel Cell). Research on this cell type is being driven in cooperation with the Graz fuel cell company ALPPS Fuel Cell Systems. The targets are ceramic tubes with 50mm length and a diameter of 3 - 5mm (see photo).