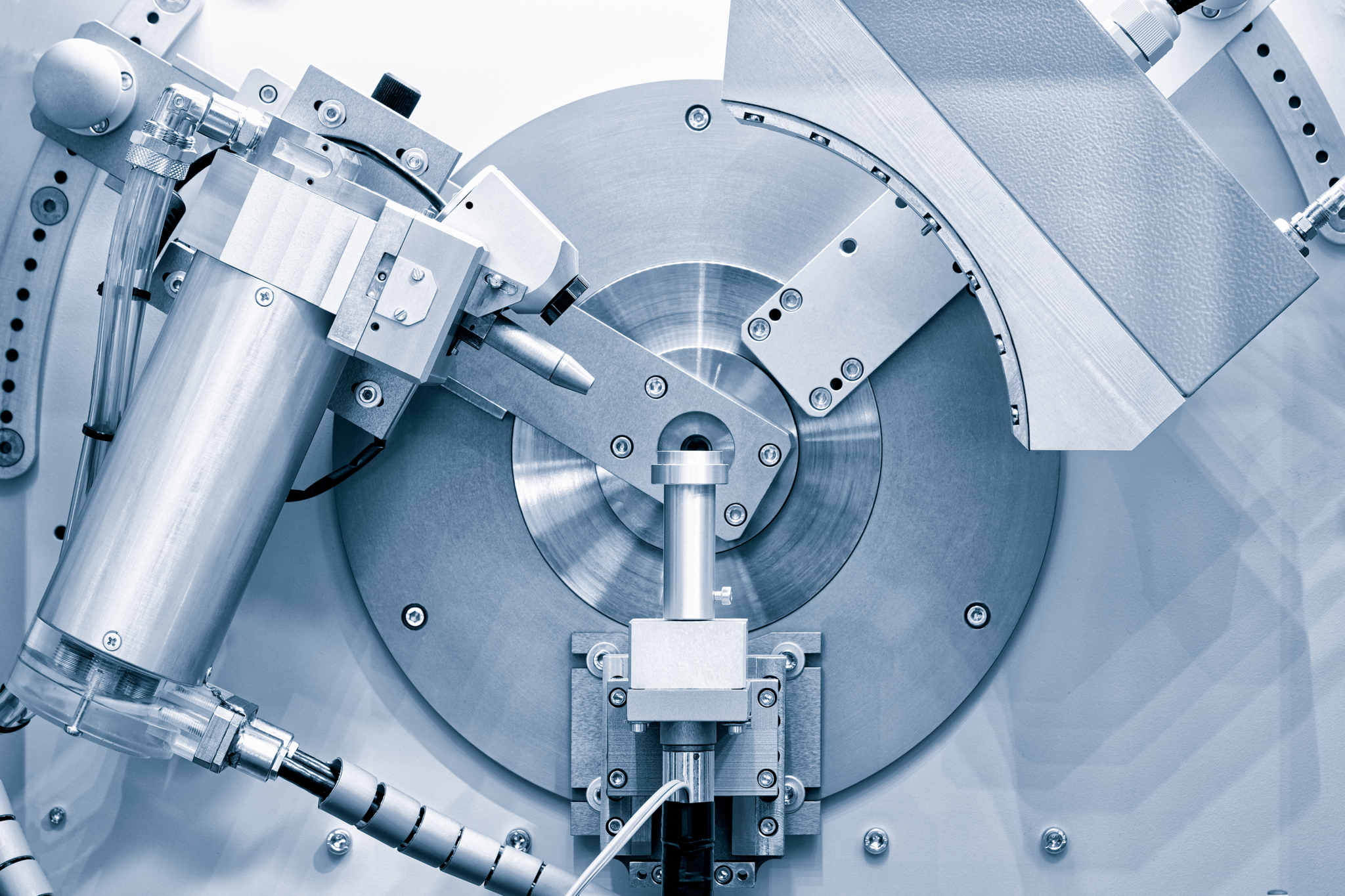

Focal Area Materials

Materials with defined properties are the basis for both highly specialised applications and everyday products. Research is carried out along the entire process chain, from material selection and modification to the finished component. Polymers, composites, metals and surface coatings as well as the non-destructive testing methods 3D X-ray computed tomography (CT) and active thermography are at the centre of the research work.

Materials and production engineering

This topic focuses on the optimised, material-specific processing of polymer materials, composites and metals and their testing. Specifically, the Materials specialisation area is dedicated to the following areas:

- Polymer processing and the polymer cycle

- Forming technology and additive manufacturing

- Heat treatment technology

- Surface technology

- Metallurgy and alloy development

Polymer technology concentrates on plastics processing, with a special focus on process development and modelling, rheology, wetting and adhesion as well as the plastics cycle. In metallurgy, the focus is on improving the properties of tool steels and modern steels for lightweight construction. One working group is concerned with the production of surface coatings for metallic components as well as polymers glass and textiles. State-of-the-art infrastructure is available for carrying out research work.

Measuring and testing technology

Measuring and testing technology are key areas of our research and focus on the non-destructive testing of materials and components. A central role is attributed to 3D X-ray computed tomography (CT) and active thermography. CT captures the inner workings of 3D structures (metals, plastics, etc.) non-destructively and characterises materials three-dimensionally with a resolution of up to 250 nm. Active thermal measurement methods are rapid imaging methods for analysing a heat flow previously excited in the test specimen using infrared cameras. They provide information about defects inside the object or material properties. In addition, projects are carried out in connection with optical measurement technology, sound and vibration technology and industrial image processing.

TCKT - Transfercenter für Kunststofftechnik GmbH

The TCKT stands for application-orientated research and development in all areas of polymer technology. In addition to problem solving within the framework of research projects, a broad range of services is offered in the contract sector (individual material tests, longer-term studies). Since May 2022, the TCKT has been a 100% subsidiary of the FH Upper Austria.

Contact - Head of Focal Area Materials

FH-Prof. Priv.-Doz. Dipl.-Ing. Dr.mont. Gernot Zitzenbacher

Professor

of Polymer Processing

I'll help you choose your study program.